diesel biomass pellet mill

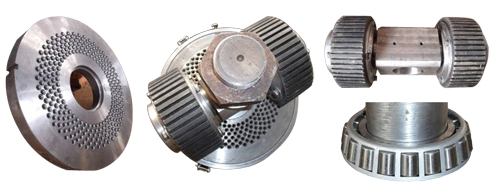

Our diesel biomass pellet mill is also flat die designed, and especially made for home use and individual usage. It is driven by diesel engine and the die inside the machine is horizontal with a series of rollers above. When the biomass materials are put into the feeder of the diesel engine biomass pellet press, they will fall down into the area between the flat die and the rollers. The rollers will compress these materials into the small holes of the flat die to form pellets. Once the biomass pellets emerge on the other side of the flat die, a series of stationary knives will cut them into the same pre-determined length immediately. Thus, final biomass pellets are made.

Technical Parameter of Diesel Biomass Pellet Mill

| Type | Power (Hp) | Output (kg/h) | Weight (kg) | Package size (mm) |

|---|---|---|---|---|

| ZLSP-150A | 8 | 50-100 | 180/220 | 1000*500*750 |

| ZLSP-200A | 15 | 80-120 | 210/240 | 1460*750*900 |

| ZLSP-230A | 22 | 120-200 | 280/310 | 1560*850*1000 |

| ZLSP-260A | 30 | 160-250 | 330/360 | 1200*500*1070 |

| ZLSP-300A | 55 | 250-400 | 410/450 | 1220*600*1000 |

Video of Diesel Biomass Pellet Mill

Advantages of Diesel Biomass Pellet Mill

- Driven by the diesel engine, this pellet mill is a good choice in the area where is short of electricity or electricity is expensive.

- The diesel engine biomass pellet mill is equipped with clutch and accelerating-decelerating device to change its running speed.

- The pellet mill also adopts the screw-center to adjust the pressure structure.

- This diesel engine biomass pellet mill can press many different kinds of pellets via different models of pore diameter and various compression ratios.

- Like other models of our pellet mills, this pellet press also engines the advantages of small size, simple design, compact structure, low power consumption, easy operation and maintenance, low noise, and long service life.

How to start the diesel biomass pellet mill?

Diesel Biomass Pellet Mill (without electric starter)- Turn on the speed controlling handle.

- Insert the start crank into the hole of the start shaft. Then pres down decompression handle with the left hand, and roll the start crank with your right hand until you hear the normal diesel engine running sound.

- Roll the start crank fast. Release the decompression handle quickly when the fly wheel gets enough power. Then roll the start crank continuously till the diesel engine is started.

- When the diesel engine starts to run, pull back the start handle in time to stop the start crank dropping away from the start hole.

- Turn on the speed controller.

- Turn the circuit key to the gear “I”, and then the starter is connected with the storage battery. Turn the circuit key to the gear “II”, and then the diesel engine starts.

- After the diesel engine starts, turn the circuit key to the gear “I” again.

Product Brochures,Instant FREEDownload

We Respect Your Email Privacy, We Hate Spam As Much As You Do!