As a leading manufacturer and supplier of pellet mills in China, GEMCO machinery has many significant advantages compared with the pellets processing machines of other manufacturers.

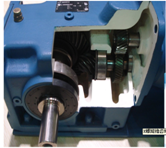

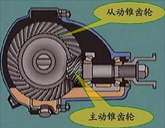

1. Transmission structure: GEMCO pellet mills adopt the latest advanced technology.

| Advantages | GEMCO | Machines of Other Manufacturers |

| Reduction gear | Bevel gear | |

1.low noise2.rotating both forward and reverse3.gear has long service life |

1.low investment2. easy maintenance |

2. Raw materials of key components

GEMCO dies and main axis are made of 40Cr, while these of other manufacturers are made of 45# steel.

| 40Cr/4Cr13 | 45# steel | |

| Advantages | 1. high content of 40Cr, more wear-resisting2. forging materials, and their mechanics performance has been improved | 1. low intensity2. poor abrasion resistance |

3. Heat treatment: The dies, main axis, and rollers of GEMCO are processed by vacuum treatment, while other manufacturers treat these components via carburizing and quenching. Consequently, GEMCO machines are more superior in mold hardness, wear resistance, and service life.

| vacuum heating treatment | carburizing & quenching | |

| Advantages | 1. no damage to the surface quality of key components2. cause tiny deformation of components | 1. the hardness layer is thin, and the die only has short service life2. cause large deformation of components |

4. Components Sealing

| GEMCO | Machines of Other Manufacturers | |

| Common Components | both ends of the bearing are sealed | only one end of the roller bearing is sealed |

| Plastic Components | mechanical seal and oil seal effectively solve the problem of plastic’s electrostatic adsorption | no similar components |

5. Hopper Seal: The feed hopper and discharging hopper are made of galvanized sheet, which avoids corrosion and prolongs its service life.

6. Fastening Details: Adjust properly the space between the die and the rollers, which ensures that screw thread has no deformation or damage.

GEMCO |

Other Suppliers |

7. Other Comparisons between GEMCO Machinery and Others

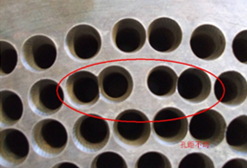

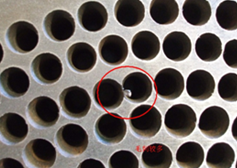

Dies of GEMCO

Dies of Other Manufacturers

Electrical Controlling Part

| Electric Cabinet | GEMCO | Other Manufacturers |

| Outside Appearance |  |

|

| Inside

|

|

|

| Emergency Stop |  |

|

Packaging: GEMCO adopts the professional fumigation-free packing board, which leaves out fumigation in export. Besides, GEMCO machines are wrapped in plastic film to avoid corrosion in transport.

| Packaging | GEMCO | Other Manufactureres |

| First step: Wrap the machine and its components in plastic film to make it moistureproof. |  |

|

| Second step: Fix well every component separately. |  |

|

| Third step: Sealing. |  |

|