rotating roller pellet mill

Rotating roller pellet mill is flat die designed to make pellets from various biomass materials. The biomass pellet mill is suitable for processing sawdust, wood shavings, wood chips, rice husks, straw, grass, alfalfa, peanut shells, chaff, bamboo shavings, bagasse and alfalfa, etc.The rotating roller biomass pellets making machine has gained good reputation worldwide due to its efficiency, stability, durability and safety since it has been put into market. Furthermore, our customers, both domestic and overseas, are pretty satisfied with this kind of biomass pellet press.

Rotating Roller Pellet Mill with Electric Motor

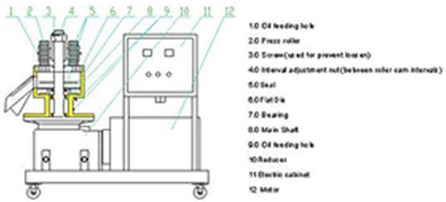

Structure of Rotating Roller Pellet Mill with Electric Motor

Technical Parameter of Rotating Roller Pellet Mill with Electric Motor

| Type | Power (kw) | Output (kg/h) | Weight (kg) | Package size (mm) |

|---|---|---|---|---|

| ZLSP-200B | Three phase7.5 | 80-120 | 215/245 | 950*450*1050 |

| ZLSP-300B | Three phase 22 | 250-350 | 540/575 | 1350*750*1400 |

| ZLSP-400B | Three phase 30 | 350-450 | 770/810 | 1400*800*1450 |

Rotating Roller Pellet Mill with Diesel Engine

Technical Parameter of Rotating Roller Pellet Mill with Diesel Engine

| Type | Power (Hp) | Output (kg/h) | Weight (kg) | Package size (mm) |

|---|---|---|---|---|

| ZLSP-200A | 15 | 80-120 | 320/350 | 1460*950*1100 |

| ZLSP-300A | 36 | 250-350 | 850/890 | 1100*700*2480 |

| ZLSP-400A | 55 | 350-450 | 1010/1050 | 1300*800*2600 |

Working Principle of Rotating Roller Pellet Mill

The rotating roller pellet mill has a series of rotating rollers and a stationary die. When the pellet machine is in operation, the die is stationary while the rollers are rotating. The great force between the rollers and the flat die will press the powders of raw materials through the holes in the die to form biomass pellets. The rotating roller biomass pellet press’ design prolongs its service life, which is about 2000 hours. Besides, the quality and length of the finished biomass pellets are much smoother and longer.

The diameter of final finished biomass pellets is from 6mm to 10mm. The flat die and the rollers are both made of high-quality alloy steel, and their service life is at least over 800 hours.

Besides, the usable life of motor and gear box is 1 year; the upper body and box of main shaft is 5 years; for others not stated here: 1 year.

The diameter of final finished biomass pellets is from 6mm to 10mm. The flat die and the rollers are both made of high-quality alloy steel, and their service life is at least over 800 hours.

Besides, the usable life of motor and gear box is 1 year; the upper body and box of main shaft is 5 years; for others not stated here: 1 year.

Biomass Pellets

Biomass pellets are a kind of clean, efficient, cost-effective, convenient, economical, renewable, and environmentally friendly fuel. They are made of various kinds of biomass materials, such as: rice husks, wood shavings, wood chips, sawdust, straw, alfalfa, bagasse, peanut shells and forest waste, etc.

How are biomass pellets made?

The biomass materials need to be pulverized into small particles first. And then make sure they contain the proper moisture, usually less than 15%. Then put these biomass powders into the feeder of the pellet mill, and they will be pressed by a series of rollers into the small holes of the die inside the pellet machine. Due to the high temperature and strong pressure inside the pellet press, the lignin, naturally contained in the biomass materials, melts and acts as a "binder" stitching together fibers to form an extruded pellet section and helping to keep the shape of pellets as they are dried.

Product Brochures,Instant FREEDownload

We Respect Your Email Privacy, We Hate Spam As Much As You Do!